The Most Versatile Coaters for the Digital Market

Capitalizing on our offset coating expertise, Epic Products developed versatile coaters for the digital printing market. These coaters are fully automated and consistently apply UV or aqueous coating.

Epic CT-660™ and CT-660XD –Off-Line Coating Systems

The Epic CT-660 and CT-660XD are the most versatile digital coaters on the market. These coaters outperform the most advanced roller coaters. Using offset coating technology and advanced electronics, they support a broad range of coatings and can spot, flood or security coat 4,000 sheets per hour. The CT-660XD has extended deliver for improved coating flow and lay down, critical for high viscosity coatings such as blister, grit or SoftTouch. These versatile coaters can also be used to pretreat substrates with Sapphire or DigiPrime.

The Epic CT-660 and CT-660XD are the most versatile digital coaters on the market. These coaters outperform the most advanced roller coaters. Using offset coating technology and advanced electronics, they support a broad range of coatings and can spot, flood or security coat 4,000 sheets per hour. The CT-660XD has extended deliver for improved coating flow and lay down, critical for high viscosity coatings such as blister, grit or SoftTouch. These versatile coaters can also be used to pretreat substrates with Sapphire or DigiPrime.

- Easy-to-use operator interface, quick set-ups, no roller adjustments

- Changes in paper weight made via keypad input

- Fast changeover between coating types

- Two minutes warm-up time – automatic shut-off after run

- Zero make-ready sheets at start-up, preserves the integrity of variable data

- Applies an even and consistent coating on every sheet

- Completely enclosed system – no UV light leakage

- No coating odor in pressroom – internal blower exhausts through an outside duct

- Accommodates larger sheet sizes (max. 20″ X 26″) and various sheet weights

- Pre-treat HP Indigo substrates with Sapphire or DigiPrime in aqueous mode

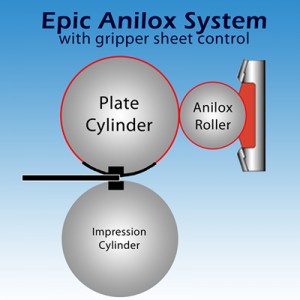

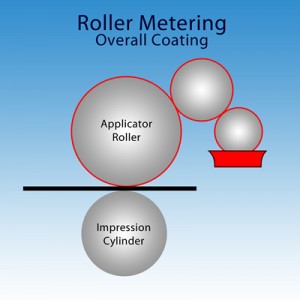

- Offers anilox metering, chamber doctor blade metering system and gripper sheet control

- Aqueous or UV coating capable, with quick changeover

- Sheet tracking software and pneumatic shutter for UV curing lamp

- Supports a wide array of finishes: gloss, matte, satin, metallic or pearl

- Spot, security or knock-outs made possible via flexographic plate

- Printed and coated sheets emerge ready to ship or move to finishing

- Productivity: 4,000 IPH, UV or Aqueous

- Sheet Size: 7” (178mm) x 7” (178mm) to 20″ (508mm) x 26″ (660.4mm)

- Paper Stock: 80 lb. text to 24 pt. board stock (116 – 400 gsm)

- Dimensions: L 180” (4572mm) x W 42” (1066mm) x H 58” (1473mm)

- Power: Single phase – USA/Canada: 208-230VAC, 60Hz, 50 amp – International: 208-230VAC, 50Hz, 50 am

- The CT-660 is equipped with anilox metering technology, which precisely applies an even and consistent coating on every sheet. This system eliminates lengthy set-up times and coating inconsistencies often associated with roller metering. Additionally, anilox allows the CT-660 to apply specialty coatings such as metallics and pearls.

CTi-635™ – In-Line Coating System for Xerox® iGen®

The Epic CTi-635 operates in-line with iGen presses, including the iGen 150 supporting 26″ sheet. It offers iGen users coating flexibility and

The Epic CTi-635 operates in-line with iGen presses, including the iGen 150 supporting 26″ sheet. It offers iGen users coating flexibility and

functionality without loss in productivity. In recognition of our commitment to the advancement of digital coating, Xerox has chosen Epic

Products as an Innovation Partner. The Epic CTi-635 is also an integral component of the Xerox Automated Packaging Solution for folding carton manufacturing.

The line integrates the iGen press with the versatile CTi-635 coater, a buffering stacker and a custom die cutter.

- Designed uniquely for the Xerox digital presses

- Runs at iGen production speeds

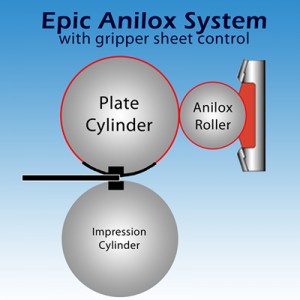

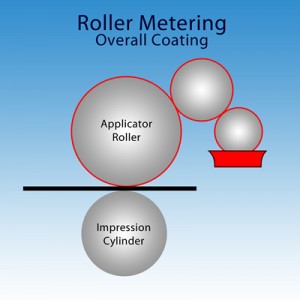

- Applies a consistent coating on long or short runs – supported by CoatTech™ anilox coating technology

- Sheets emerge dry and ready for use

- Seamless communication between coater and press via Xerox DFA interface

- Easy-to-use controls and smooth integration with press

- Prints are automatically delivered to the coating station – no additional handling required

- Flexographic plate controls coating registration

- Applies aqueous or UV coating with quick changeover

- Supports a wide array of finishes: gloss, matte, satin, metallic or pearl

- Spot, security or knock-outs made possible via plate

- Printed and coated sheets emerge ready to ship or move to near-line finishing

- Productivity Rated Speed: 30 – 40 – 50 ppm

- Sheet Size: 7” x 16.19” to 14.33” x 26”

- Paper Stock: 80 lb. text to 24pt. board (140 – 350 gsm) – Coated Stock Only

- Dimensions: L 180” (4572 mm) x W 42” (1066mm) x H 58” (1473mm)

- Power: Single Phase – USA/Canada: 208-230VAC, 60Hz, 50 amp – International: 240VAC, 50Hz, 50 amp

- External venting required

and coating inconsistencies often associated with roller metering. Additionally, anilox allows the CTi-635 to apply specialty coatings such as metallics and pearls.